嘉能可(Glencore)和 Li-Cycle 宣布计划建设欧洲最大的电池回收工厂

位于意大利波托韦斯梅的电池回收厂将成为欧洲最大的回收电池级锂来源。

北美领先的锂离子电池回收商Li-Cycle与锂离子电池生产关键矿物的领先生产商和回收商嘉能可国际公司 (Glencore International AG) 签署了一份意向书,将在北美意大利波托韦斯梅开发一家电池回收厂。该工厂将从回收电池中生产锂、镍和钴等关键电池材料。

新的电池回收工厂预计将成为欧洲最大的可持续电池级产品生产商。

大量现有基础设施

Portovesme 中心位于撒丁岛,由一座铅锌冶炼厂和湿法冶金设施组成,于 1929 年首次投入运营。嘉能可拥有旧的铅精炼厂,旨在将其改造成一座工厂,帮助其重复利用昂贵的电池金属。

拟建的电池回收厂拥有港口、公用设施、湿法冶金设施的加工设备以及经验丰富的员工队伍。

©shutterstock/萨汉·努霍格鲁

“通过重新利用我们的 Portovesme 工厂建立一个中心,该工厂可能成为嘉能可第一个生产电池级锂的资产,将使我们能够真正为我们的欧洲 OEM 和超级工厂客户在供应链的各个方面实现闭环”,嘉能可全球回收主管 Kunal Sinha 评论道。

电池回收厂将于 2026 年底或 2027 年初投入运行

两家公司将在宣布后 60 天内开始对该项目进行最终的可行性研究。预计将于 2024 年中期完成。

在双方做出最终投资决定后,该项目将进入施工阶段,Portovesme Hub 预计将于 2026 年底至 2027 年初开始调试。

嘉能可和Li-Cycle还计划成立一家合资企业,重新利用位于波托韦斯梅的现有嘉能可冶金联合体的一部分。这将有助于制定具有成本效益且快速的开发计划。

Portovesme 将成为欧洲首个投入使用的同类和规模设施

一旦投入运营,电池回收厂每年的黑色物质处理能力将高达 50,000 至 70,000 吨,相当于 36 GWh 的锂离子电池。该工厂加工的黑色物质预计将由 Li-Cycle 在欧洲不断扩大的 Spoke 网络以及嘉能可的商业网络供应。

Li-Cycle 的 Spoke 网络和嘉能可的电池循环平台将帮助欧洲更接近制造废料和报废电池的闭环。

Li-Cycle 联合创始人兼执行主席 Tim Johnston 评论道:“规划中的 Portovesme Hub 是欧洲电池回收行业的一个里程碑式项目,预计将成为欧洲大陆最大的回收电池级锂来源。我们很高兴能够扩大与嘉能可的全球战略合作伙伴关系,并借鉴罗彻斯特中心的经验教训,以环保的方式支持锂离子电池生态系统的快速发展。”

信息来源:Innovation News Network

原文:

© shutterstock/THINK A

The battery recycling plant located in Portovesme, Italy would be the largest source of recycled battery-grade lithium in Europe.

Li-Cycle, the leading lithium-ion battery recycler in North America, and Glencore International AG, a leading producer and recycler of critical minerals for the production of lithium-ion batteries, have signed a Letter of Intent to develop a battery recycling plant in Portovesme, Italy. The plant would produce critical battery materials, such as lithium, nickel, and cobalt, from recycled batteries.

The new battery recycling plant is expected to be the largest producer of sustainable battery-grade products in Europe.

Substantial existing infrastructure

Located in Sardinia, the Portovesme hub consists of a lead-zinc smelter and hydrometallurgical facility which first started operations in 1929. Glencore owns the old lead refinery and aims to convert it into a plant that will help it reuse expensive battery metals.

The proposed battery recycling plant has access to a port, utilities, processing equipment from the hydrometallurgical facility, and an experienced workforce.

© shutterstock/Sahan Nuhoglu

“Establishing a Hub through the re-purposing of our Portovesme site, which could become the first Glencore asset to produce battery-grade lithium, will enable us to truly close the loop for our European OEM and gigafactory customers across all aspects of the supply chain,” commented Kunal Sinha, Global Head of Recycling, at Glencore.

The battery recycling plant could be commissioned by late 2026 or early 2027

The companies will commence a definitive feasibility study for this project within 60 days of the announcement. This is expected to be completed by mid-2024.

After a final investment decision by the parties, the project will process to construction with commissioning of the Portovesme Hub expected to commence in late 2026 to early 2027.

Glencore and Li-Cycle also expect to form a joint venture that would repurpose part of the existing Glencore metallurgical complex in Portovesme. This would enable a cost-efficient and expedited development plan.

Portovesme will be the first facility of its kind and scale to come online in Europe

Once operational, the battery recycling plant will have a processing capacity of up to 50,000 to 70,000 tonnes of black mass annually, or the equivalent of up to 36 GWh of lithium-ion batteries. The black mass processed at the plant is expected to be supplied from Li-Cycle’s growing Spoke network in Europe and through Glencore’s commercial network.

Li-Cycle’s Spoke network and Glencore’s battery circularity platform will help Europe to get one step closer to closing the loop on manufacturing scrap and end-of-life batteries.

Tim Johnston, co-founder and Executive Chair, Li-Cycle, commented: “The planned Portovesme Hub is a landmark project for Europe’s battery recycling industry and is expected to be the largest source of recycled battery-grade lithium on the continent. We are excited to expand our global strategic partnership with Glencore and build on our learnings from the Rochester Hub in support of the rapid growth of the lithium-ion battery ecosystem in an environmentally friendly manner.”

BRS2023 | 中国国际动力电池回收峰会

China International Power Battery Recycling Summit 2023

October 26-27, 2023 Shanghai, China

会议语言:中英双语(提供同传)

峰会热点话题

“责任主体”制度及回收体系建设

Responsibility subject system, and the construction of recycling channels

国内外动力电池回收利用先进技术与运营模式分享

Sharing of advanced technology and operation mode for battery recycling at home and abroad

电池回收中的污染控制及环境管理要求

Pollution control and environmental management requirements in power battery recycling

安全+经济的废旧锂电池资源化预处理技术

Safe, efficient and environmental pre-treatment technology for battery recycling

废旧动力锂电池材料有价金属高效分离提取技术

Efficient metal separation technology for waste power battery

电池负极材料及电解液回收利用

Recycling and utilization of waste lithium battery negative electrode materials and electrolytes

退役动力电池的分选评估及梯次利用

Sorting evaluation and cascade utilization of retired power batteries

回收利用中的碳排放核算及碳减排策略

Carbon emission accounting and carbon reduction strategies in recycling

… 以及更多!

And many more!

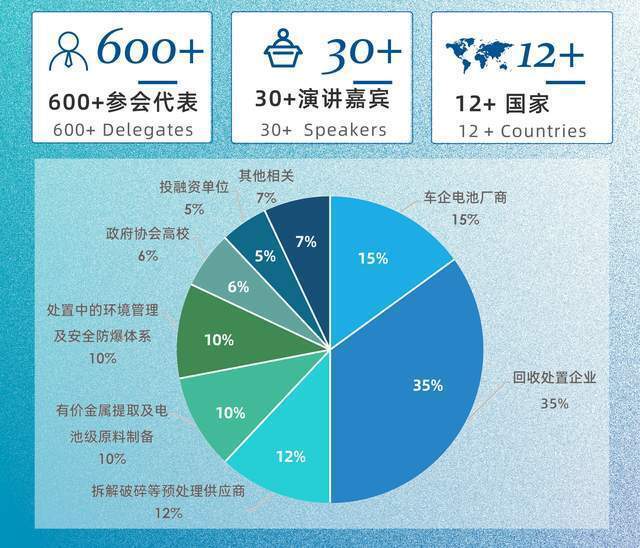

嘉宾组成

- 2024-10-15

- 2024-09-24

- 2024-09-24

- 2024-09-11

- 2024-06-19

- 2024-06-13

- 2024-06-11

- 2023-11-08

- 2023-11-03

- 2023-07-19

- 2023-07-06

- 2023-07-05

- 2023-07-05

- 2023-06-28

- 2023-06-20

- 2023-06-19

- 2023-05-31

- 2023-05-31

- 2023-05-26

- 2023-05-26

- 2023-05-25

- 2023-05-24